Plastic punching bags can be seen almost everywhere in daily life, and almost everyone has used them. However, they are not familiar with the customization process of punching four finger bags. Today, I will share with you the customization process of punching four finger bags.

Step 1: Determine the style of the punched four finger bag

When we need to order punched four finger bags, we need to communicate with the manufacturer about the required bag size and printing requirements. Here, we will explain that since it is customized, the size must be tailored to your daily use, which can save materials and meet your needs. Secondly, in terms of printing logos, it is recommended to choose simple and generous logos, because the more complex the logo, the higher the cost.

Step 2: Punching four finger bag blown film printing

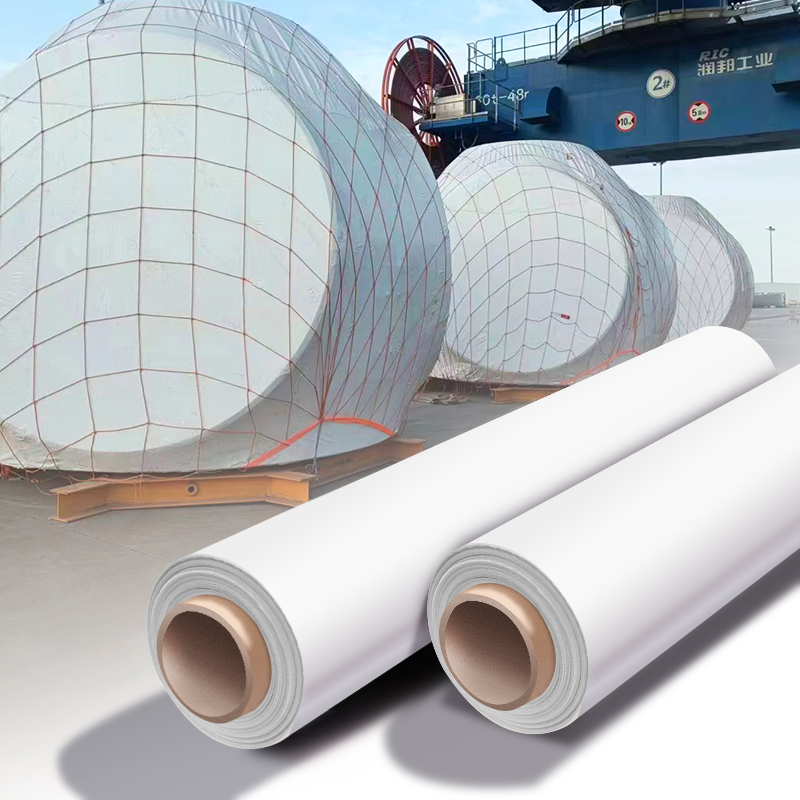

After determining the size and printing requirements with the punching four finger bag manufacturer, the manufacturer will blow the film in one row according to the order requirements. The punching four finger bag is initially cylindrical in production, and the semi-finished product looks like a roll of connected film, which is convenient for logo printing in the future.

Step 3: Punching four finger bags to make bags

After undergoing printing, the four finger bag has already been preliminarily formed, but to achieve the style of a flat mouth punched four finger bag, it needs to go through the bag making process. Bag making involves cutting the printed cylinder film according to size ratio, welding the bottom row, and the handle part is made by dividing the handle part in a punching machine.

4000538828

4000538828